PVC vs. Polypropylene: Safe Flue Gas Venting with Centrotherm

When choosing a venting material, the debate of PVC vs. polypropylene is critical. Both are widely used in flue gas systems, but they are not created equal, especially for high-efficiency boilers, furnaces, and water heaters.

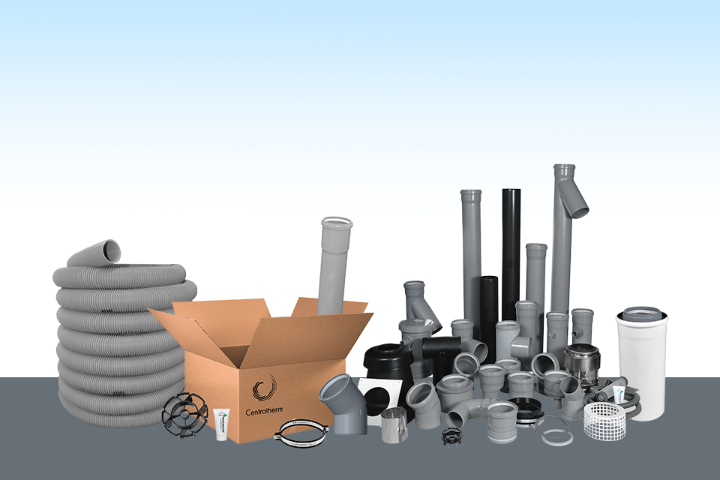

While PVC pipe may be inexpensive, PVC, which stands for polyvinyl chloride, is not designed for venting hot flue gases. In contrast, polypropylene pipe, such as Centrotherm’s InnoFlue® and InnoFlue® Lite polypropylene piping systems, are engineered for safe, cost-effective flue gas venting and are designed to work seamlessly with your high efficiency heating system.

Choosing polypropylene vs. PVC for high-efficiency boilers, furnaces, and water heaters impacts system safety, long-term performance, and compliance with North American standards.

At Centrotherm, we provide advanced polypropylene flue gas venting solutions that deliver the safety, performance, and compliance that PVC cannot match in North America for flue gas venting.

Why Polypropylene Outperforms PVC Pipe

The PVC vs. polypropylene comparison highlights one major theme: safety and reliability.

Safety and UL 1738 Compliance

When it comes to venting safety, compliance with recognized standards is critical. In the United States, UL 1738 certifies venting systems for flue gases, while in Canada the equivalent is ULC-S636. InnoFlue® Lite does not include the flame retardants required for UL 1738, however, it does meet the European Standard, CE EN 14471.

In The US, UL 1738 (Standard for Venting Systems for Gas-Burning Appliances, Categories II, III, and IV) defines requirements for safe venting.

- PVC pipe is not UL 1738 listed, making it non-compliant and unsafe for flue gas venting.

- Polypropylene venting systems, such as Centrotherm's standard InnoFlue®, carry UL 1738 certification.

While InnoFlue® Lite does not contain flame retardants to make it UL 1738 listed, it is engineered for safe flue gas venting at a lower cost for water heaters, tankless water heaters, furnaces, and boilers. It retains the same pressure drops, maximum lengths, and termination performance as standard polypropylene systems.

Durability and Convenience

Polypropylene pipe resist heat, pressure changes, and acidic condensate common in high-efficiency appliances. InnoFlue® and InnoFlue® Lite are extremely lightweight, reducing strain for installers while maintaining a 10-year limited warranty.

Cost-Effective and Environmentally Responsible

Centrotherm’s latest solution, InnoFlue® Lite is priced competitively with Sch. 40 PVC, fully recyclable, and simplifies inventory with a reduced SKU portfolio, offering both economic and environmental benefits.

What’s the Difference between PVC and polypropylene?

The discussion around polypropylene vs. PVC centers on performance under heat, chemical stability, installation methods, and long-term safety.

Heat Resistance

PVC Pipe: PVC is rated for plumbing applications such as DWV systems, not combustion gases. When exposed to the elevated temperatures of flue gas exhaust, PVC can warp, crack, or soften creating potential safety risks.

Polypropylene: Designed to withstand flue gas exhaust, up to 230°F (110°C), without risk of degradation. InnoFlue® and InnoFlue® Lite match these ratings while being lightweight and easy to handle.

Installation and Ease of Use

PVC Pipe: PVC venting requires solvent cement or pvc glue to join sections together, which can introduce weak points over time. Improper curing or excess adhesive may lead to leaks, while glued connections also release harmful VOCs during installation. Additionally, glued joints cannot be easily adjusted once set, making installation less flexible and more time-consuming

Polypropylene: Uses gasketed connections for quick, secure installation. InnoFlue® and InnoFlue® Lite are extremely lightweight, have no cure time, and is easy for technicians to carry, maneuver, and install in tight spaces.

Appliance Compatibility

PVC Pipe: PVC manufacturers do not recommend it.

Polypropylene: Compatible with high-efficiency water heaters, tankless units, furnaces, and boilers.

In Summary:

| Feature | Centrotherm Polypropylene Pipe | PVC pipe |

| Designed for flue gas venting | ✅ Yes | ❌ No |

| UL 1738 listed | ✅ Yes | ❌ No |

| Max temperature | 230°F (110°C) | 140°F (60°C) |

| Installation | Gasketed, no glue or solvent | Glue or solvent required |

The Role of Appliance Adaptors in Venting Systems

A safe venting system is only as secure as its connections. Some new high-efficiency heating appliances come with a gasketed flue collar and do not require an appliance adaptor. For appliances that do require an appliance adaptor, Centrotherm manufactures flanged, gasketed, and sometimes unit specific appliance adaptors.

Consult the InnoFlue® online appliance adaptor database to identify the correct component for the heating appliance.

Centrotherm appliance adaptors are designed to adapt a female PVC or CPVC coupler, or an appliance flue exhaust, to InnoFlue® SW diameters, creating a secure and seamless transition. They:

- Ensure airtight seals between the appliance and venting system

- Eliminate the need for glues or solvents

- Maintain performance and compatibility with InnoFlue® Lite

With these adaptors, installers can achieve a professional, code-compliant connection, if required, quickly and easily, without compromising the efficiency or safety of the venting system.

Centrotherm: North America’s Trusted Polypropylene Solution

Centrotherm is a leader in polypropylene flue gas venting systems. Our solutions are engineered with safety, performance, and installer convenience in mind.

Key advantages include:

- UL 1738 listed polypropylene piping, where required

- InnoFlue® Lite (not UL 1738 listed): lightweight, cost-effective, and easy to install

- Gasketed connections for secure, clean assembly (no PVC glue)

- Full product portfolio, including appliance adaptors

- 10-year limited warranty for both InnoFlue® Lite and InnoFlue® standard systems

Frequently Asked Questions: PVC vs. Polypropylene

Is PVC pipe safe for venting flue gases?

No. Schedule 40 PVC solid wall or foam core plumbing DWV PVC pipe and fittings do not meet UL 1738 and are not recommended for flue gas applications by PVC manufacturers.

Why choose polypropylene over PVC?

Polypropylene is UL 1738 listed, heat-resistant, non-toxic, and fully recyclable. Centrotherm polypropylene venting systems provide long-term safety and reliability.

What temperatures can polypropylene handle compared to PVC?

InnoFlue® and InnoFlue® Lite can handle up to 230°F (110°C). PVC softens at 140°F (60°C), making it unsafe for venting.

Final Thoughts

When comparing PVC vs. polypropylene for flue gas venting, polypropylene is the safer and more reliant solution. For flue gas venting, PVC pipe is not recommended. Polypropylene venting systems, including InnoFlue® Lite, offer safe, more cost-effective, and reliable solutions for water heaters, furnaces, boilers, and tankless appliances.

When safety, performance, and efficiency matter most, Centrotherm is the trusted provider of high-quality venting solutions.

Contact Centrotherm today to learn more about InnoFlue® Lite and our full range of polypropylene venting systems.

Whether you’re ready to place an order or just exploring how Centrotherm can help with safe flue gas venting, we’d be happy to guide you. Get in touch and we’ll get back to you soon.

Contact Us

-(2).jpg?width=600&height=400&hash=%2bJIIcUtmSBjs69DGEwsL4qyLlsXn9FYZPCSYMEzYDak%3d)